Mono Fiber-optic Patch Cords

Mono Fiber-optic Patch Cords

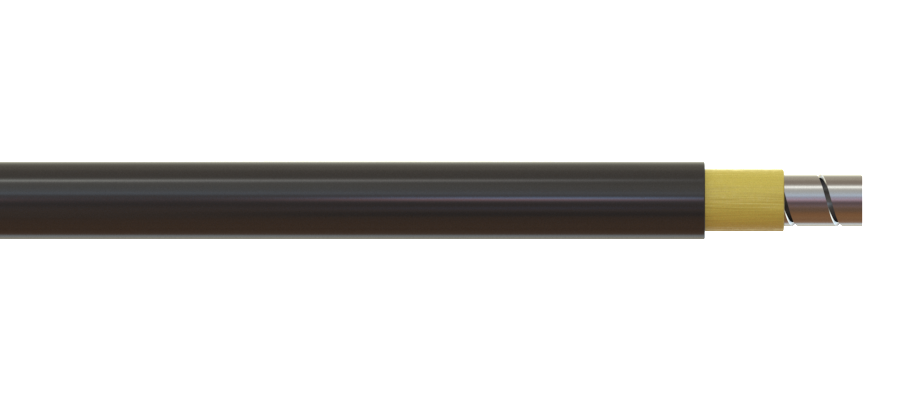

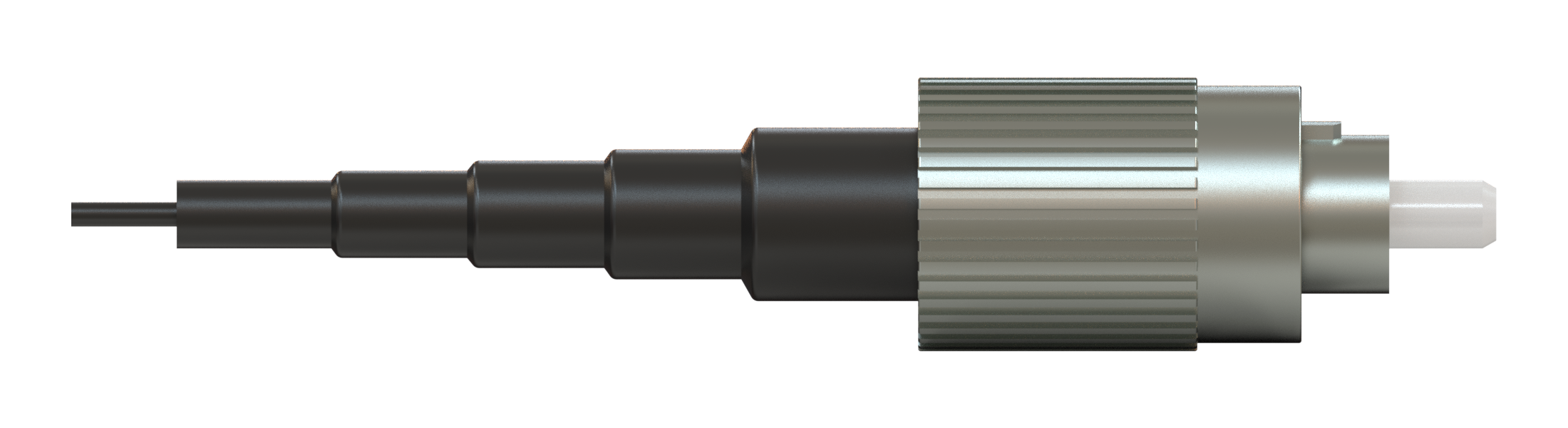

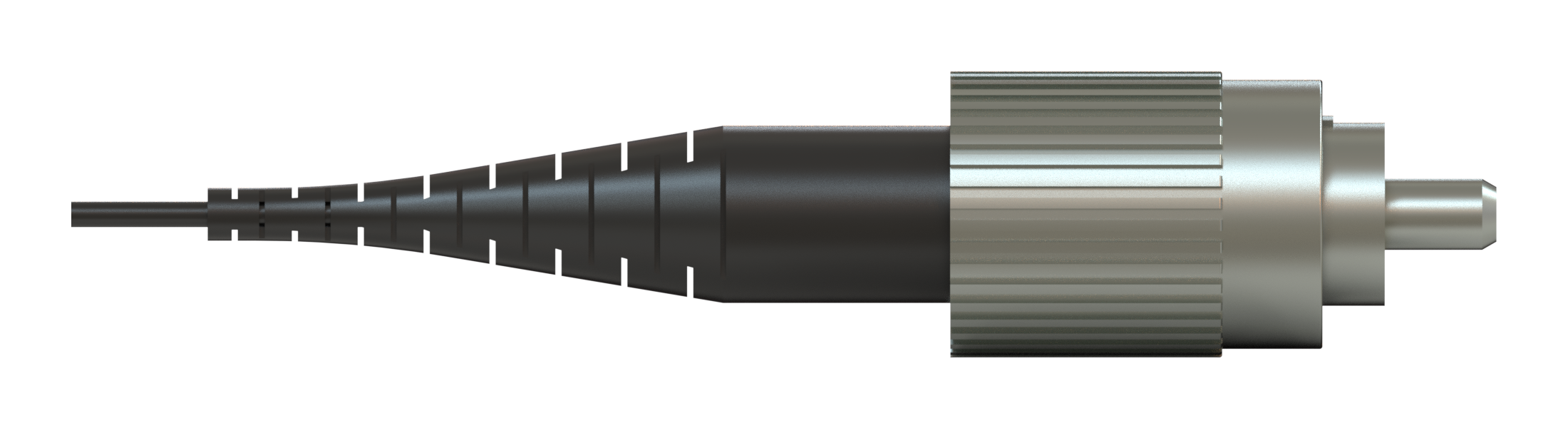

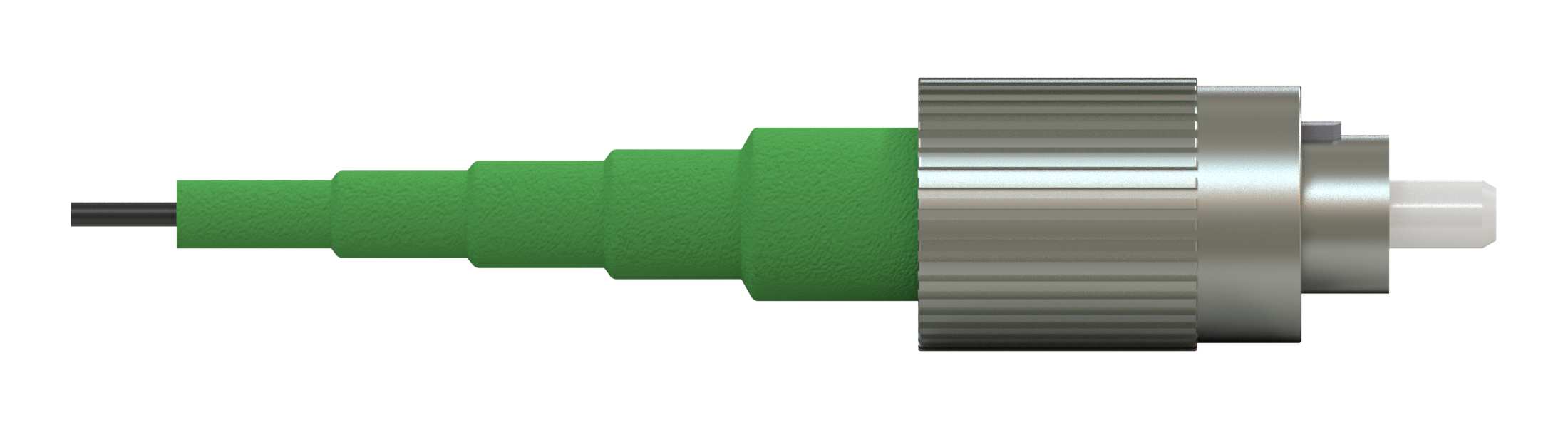

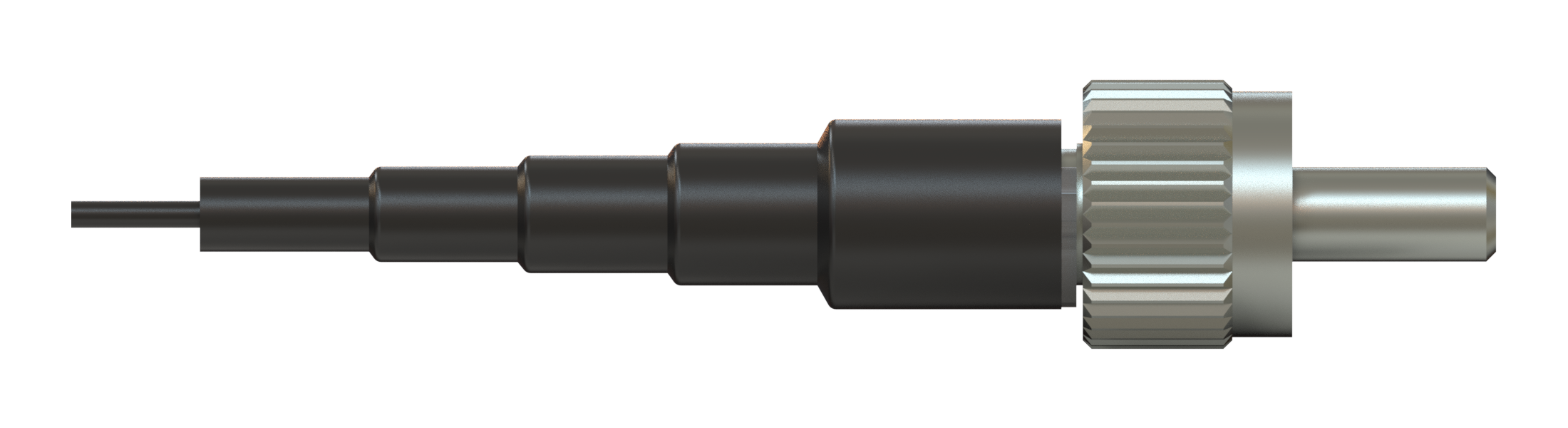

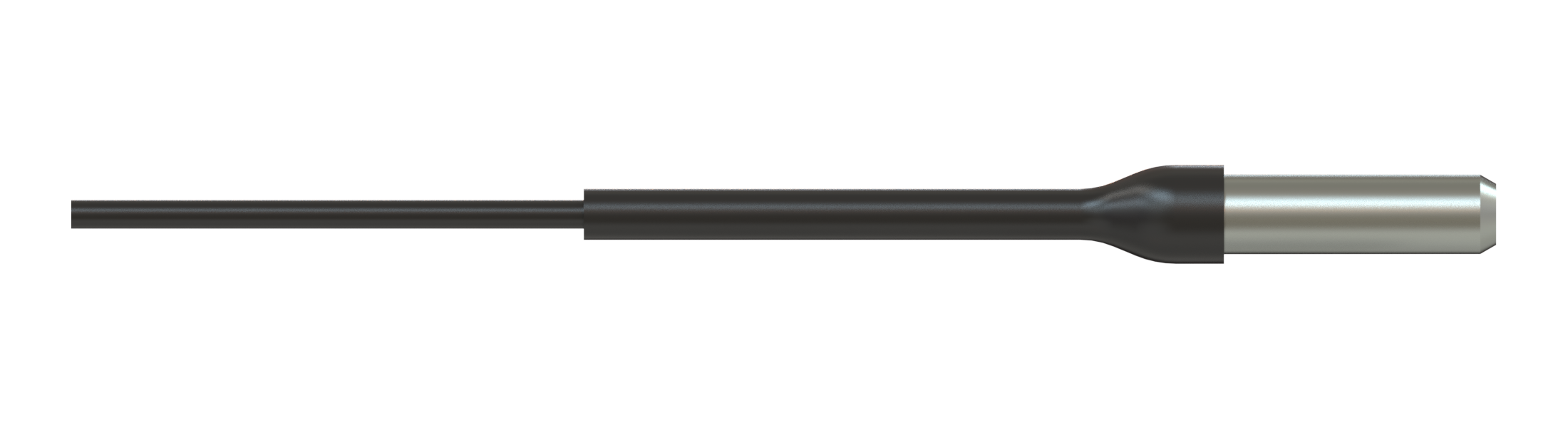

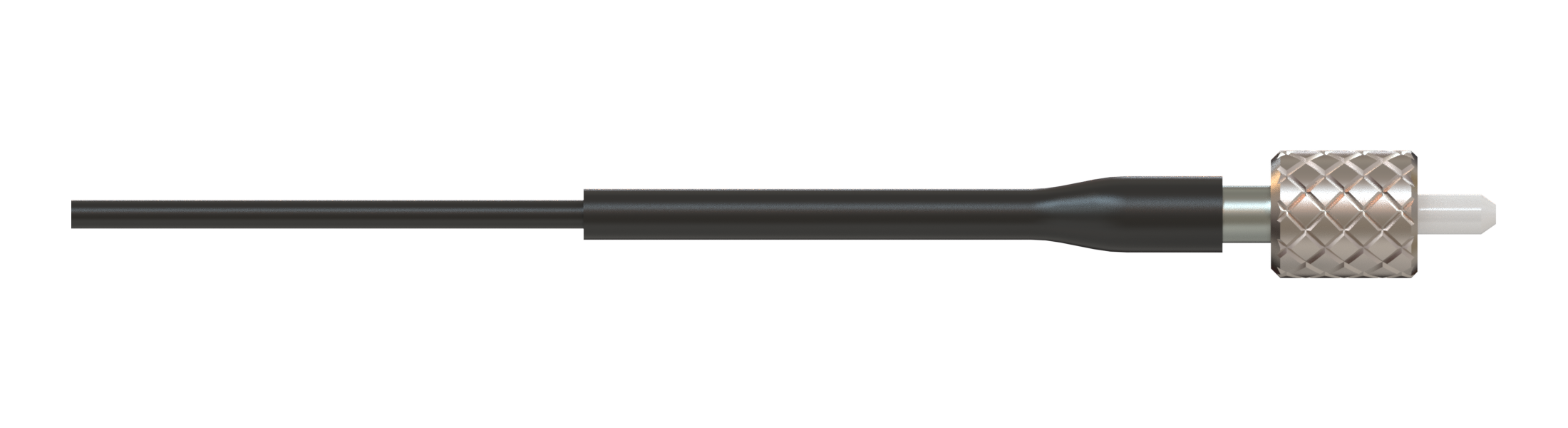

The simplest form of the fiber-optic patch cord is a single strand of optical fiber surrounded by a buffer and protective jacket with connectors at both ends.

The optical fiber core diameter and its numerical aperture (NA) define the coupling efficiency into the fiber.

The most popular optical fiber core diameters for optogenetics and fiber photometry experiments are those with 200 µm and 400 µm core diameters. As for the numerical aperture of the fiber, smaller 0.22 NA is suitable for laser light sources, while for incoherent light sources, like LEDs, it is recommended to use 0.5 NA and higher all the way from the light source to the sample.

…generating

The simplest form of the fiber-optic patch cord is a single strand of optical fiber surrounded by a buffer and protective jacket with connectors at both ends.

The optical fiber core diameter and its numerical aperture (NA) define the coupling efficiency into the fiber.

The most popular optical fiber core diameters for optogenetics and fiber photometry experiments are those with 200 µm and 400 µm core diameters. As for the numerical aperture of the fiber, smaller 0.22 NA is suitable for laser light sources, while for incoherent light sources, like LEDs, it is recommended to use 0.5 NA and higher all the way from the light source to the sample.

| Comparison Table : Patch cord Optical Fiber Type | ||||

| Optical Fiber Type | Borosilicate | Silica/Silica | Silica/Polymer | Plastic |

| Core | Glass | Glass | Glass | Plastic |

| Cladding | Glass | Glass | Polymer | Polymer |

| Numerical Aperture | 0.66 | 0.22 - 0.37 | 0.48 - 0.57 | 0.50 - 0.63 |

| Flexibility | Poor | Good | Good | Excellent |

| Auto-Fluorescence | Good | Excellent | Good | Poor |

| RECOMMENDED USE : |

||||

| Fiber Photometry | N/A (too fragile) |

Good* | Good* | Not recommended (high AF) |

| Optogenetics LED Source | N/A (too fragile) |

Not recommended (low NA) |

Good | BEST |

| Optogenetics Laser Source | N/A (too fragile) |

BEST | Good | Good |

* For Fiber photometry, we recommend low-autofluorescence optical fiber patch cords.

| Core/Cladding Material | Core Diameter (μm) | Cladding (μm) | Buffer (μm) | NA | Fiber-Optic Code* |

| Silica/Silica | 50 | 125 | 250 | 0.22 | 50/125/XXX-0.22 |

| 60 | 65 | 75 | 0.37 | 60/65/XXX-0.37 | |

| 62.5 | 125 | 250 | 0.27 | 62.5/125/XXX-0.27 | |

| 100 | 110 | 125 | 0.22 | 100/110/XXX-0.22 | |

| 100 | 110 | 125 | 0.37 | 100/110/XXX-0.37 | |

| 200 | 220 | 240 | 0.22 | 200/220/XXX-0.22 | |

| 200 | 220 | 245 | 0.37 | 200/220/XXX-0.37 | |

| 300 | 330 | 370 | 0.22 | 300/330/XXX-0.22 | |

| 300 | 330 | 360 | 0.37 | 300/330/XXX-0.37 | |

| 400 | 440 | 480 | 0.22 | 400/440/XXX-0.22 | |

| 400 | 440 | 470 | 0.37 | 400/440/XXX-0.37 | |

| 550 | 600 | 1040 | 0.22 | 550/600/XXX-0.22 | |

| 600 | 660 | 710 | 0.22 | 600/660/XXX-0.22 | |

| 600 | 660 | 710 | 0.37 | 600/660/XXX-0.37 | |

| Silica/Polymer | 200 | 230 | 500 | 0.48 | 200/230/XXX-0.48 |

| 200 | 230 | 500 | 0.57 | 200/230/XXX-0.57 | |

| 300 | 330 | 650 | 0.48 | 300/330/XXX-0.48 | |

| 400 | 430 | 730 | 0.37 | 400/430/XXX-0.37 | |

| 400 | 430 | 730 | 0.48 | 400/430/XXX-0.48 | |

| 400 | 430 | 730 | 0.57 | 400/430/XXX-0.57 | |

| 600 | 630 | 1040 | 0.48 | 600/630/XXX-0.48 | |

| Plastic/Plastic | 240 | 250 | - | 0.50 | 240/250/XXX-0.50 |

| 240 | 250 | - | 0.63 | 240/250/XXX-0.63 | |

| 480 | 500 | - | 0.50 | 480/500/XXX-0.50 | |

| 480 | 500 | - | 0.63 | 480/500/XXX-0.63 | |

| 735 | 750 | - | 0.50 | 735/750/XXX-0.50 | |

| 735 | 750 | - | 0.63 | 735/750/XXX-0.63 | |

| 960 | 1000 | - | 0.50 | 960/1000/XXX-0.50 | |

| 960 | 1000 | - | 0.63 | 960/1000/XXX-0.63 | |

| 1470 | 1500 | - | 0.50 | 1470/1500/XXX-0.50 | |

| 1960 | 2000 | - | 0.50 | 1960/2000/XXX-0.50 |

* XXX is representative of the jacket code, see Jackets tab to choose the best one for your needs

* Other color available on request.

Jacket availability may vary with optical fiber type

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)