Low-Autofluorescence Dual Fiber-optic Patch Cords

-

A Dual Fiber-optic Patch cord has two optically isolated fibers. One side ends with a dual ferrule guiding pin or a guiding socket connector. The other side of the patch cord can also end with a dual ferrule connector or with separate FC connectors for each fiber. The Dual Fiber-optic Patch Cord can transmit independent optical signals when used with a Separate Light Path 2x2 Fiber-optic Rotary Joint. Using dual patch cords with a 1x2 Fiber-optic Rotary Joint is optically more efficient but more expensive than using a branching patch cord with a 1x1 Fiber-optic Rotary Joint.

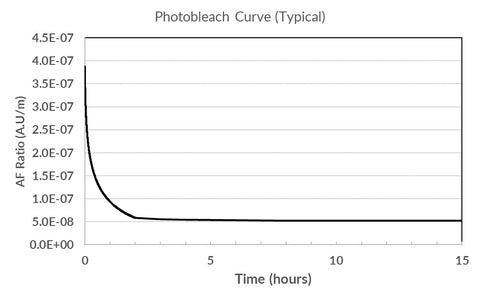

The Low Autofluorescence (LAF) Mono Patch cords are specially designed to minimize the fluorescence caused by photoactive compounds in the optical fiber and associated elements. Fibers with a low natural fluorescence are selected and used with glues, ferrules and protective coatings that have low or no-fluorescence. To ensure its minimal autofluorescence, each patch cord undergoes a 12-hour photobleaching process that decreases their remaining natural fluorescence. Doric patch cords with optical fiber having NA 0.37 use all silica glass fiber and have a very low autofluorescence level. Consequently, it is not necessary to use bleaching process on LAF patch cords with NA=0.37.

Notes:

- The autofluorescence is dependent of the length of the patch cord and the fiber core diameter. In order to minimize autofluorescence, we recommend that the patch cord should be as short as possible.

- In LAF patch cords, the photobleaching process creates a temporary and reversible decrease of autofluorescence. It is recommended to repeat this process before each use to minimize autofluorescence. The instructions are provided with the product.

- LAF patch cord use opaque black jacket to minimize ambiant light collection

-

Core

(μm)Cladding

(μm)Buffer Jacket NA Fiber-optic Code 100 110 125 900 0.37 100/110/900-0.37 200 220 245 900 0.37 200/220/900-0.37 200 230 500 900 0.57 200/230/900-0.57 400 430 730 1100

0.57 400/430/1100-0.57 400 440 470 900 0.37 400/440/900-0.37 -

* Other color available on request.

Jacket availability may vary with optical fiber type -

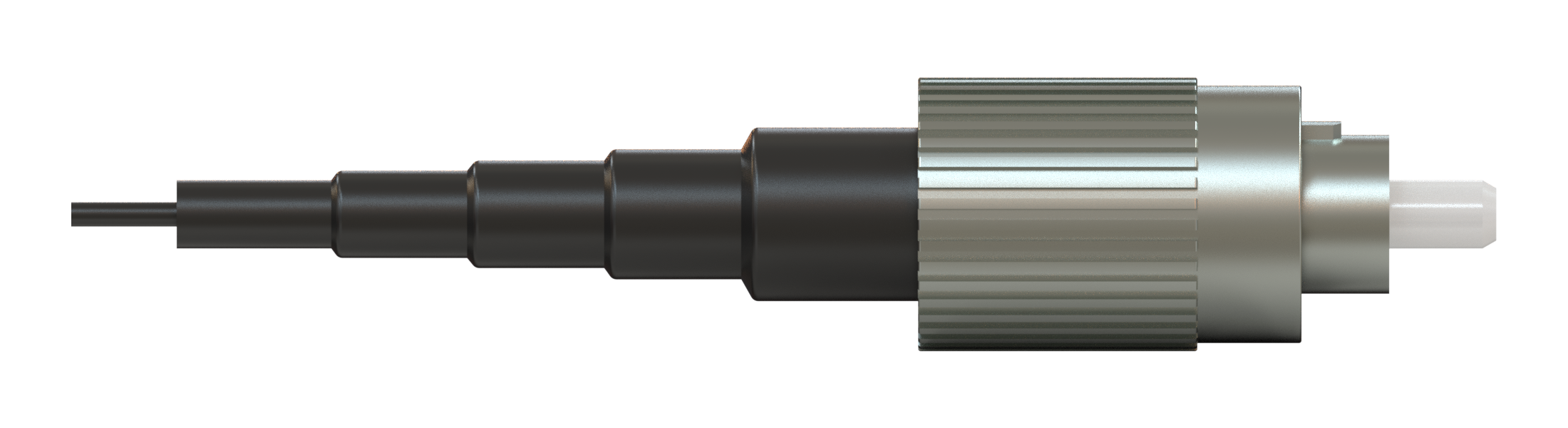

Code Description Image Drawings FC FC Connector with Zirconia Ferrule

FCM FC Connector with Metal Ferrule

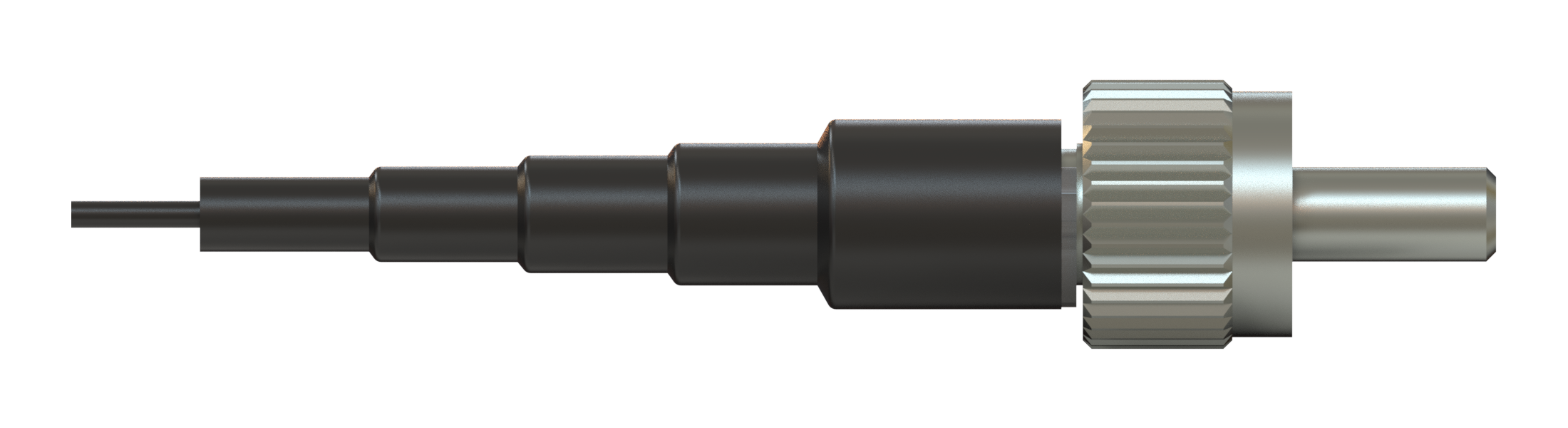

SMA SMA Connector with Metal Ferrule

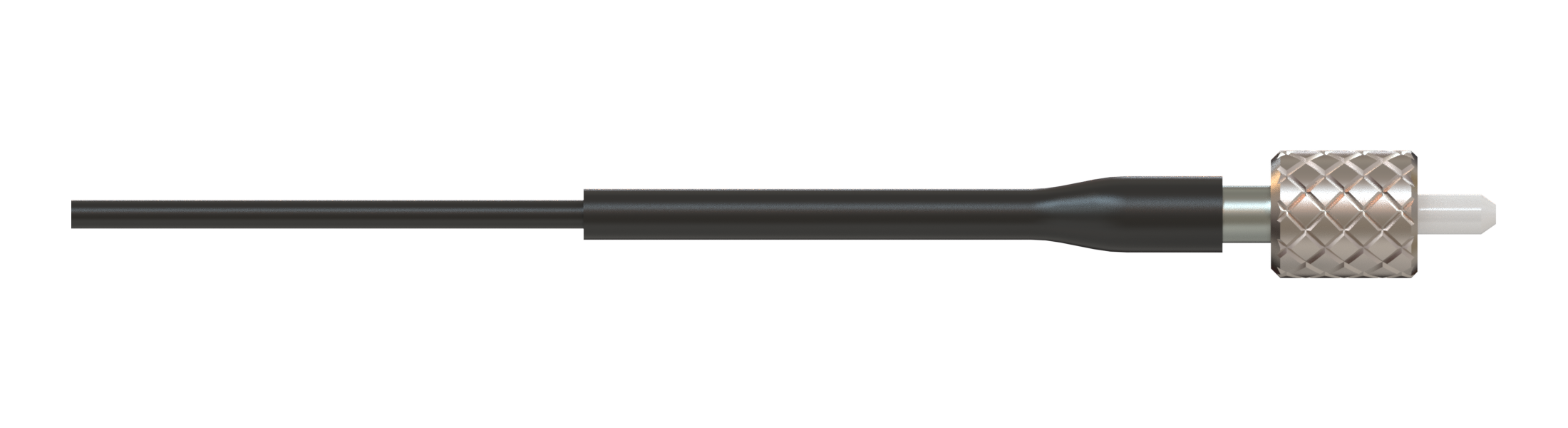

CM3 M3 Connector

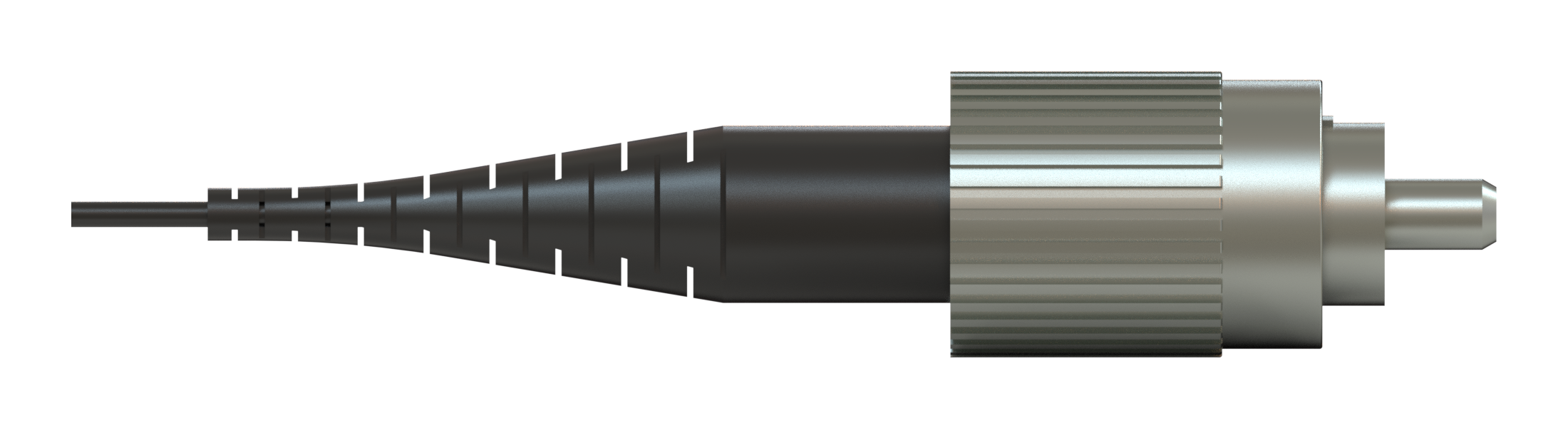

*Recommended termination for Dual Fiber-Optic Patch Cord.Code Description Image Drawings GS Guiding Socket*

Pitch from 0.7 mm to 1.7 mm

DF Dual Ferrule with a guiding pin

Pitch from 0.7 mm to 1.7 mm

-

-

Application NoteFrEn Low Autofluorescence Patch Cords

ProcedureFrEn Patch Cord Photobleaching

- le choix d'une sélection entraîne une actualisation complète de la page